Foreword

On behalf of Station Group, we extend our sincere gratitude to our valued clients and colleagues whose trust and support have fuelled our growth and strengthened our ability to meet future challenges with confidence.

Since the dawn of the new millennium, our mission has been clear: to deliver the highest quality products and services, achieve steady business growth, maintain a competitive edge, and embrace advanced technologies.

Our success is built on the combined expertise of our divisions, management, and technical teams, united by a shared ambition to excel. With an expanding network of branches across the Kingdom of Saudi Arabia, we continue to enhance our geographic presence and reinforce our commitment to serving clients with excellence.

Guided by principles of integrity and performance, STATION remains dedicated to contributing to the Kingdom's economic growth and development. We pledge to uphold our standards of excellence while continuously striving for innovation and improvement.

Managing Director – CEO

About Us

STATION For Contracting (STATION GROUP) is an ISO-certified company, multi-disciplined and specialized in diversified fields of construction services. Founded in 1978 as MERCO Waterproofing, the firm has evolved into a regional leader in composite products and specialized engineering.

Our Evolution

Since acquiring MERCO in 2002, STATION GROUP has grown from a specialized waterproofing contractor into a diversified leader in construction solutions. Our portfolio now spans architectural precast composites (UHPC, GFRC, GFRP), advanced structural restoration, concrete repair, fireproofing, building rehabilitation, interior fit-out, landscaping, metal fabrication, EIFS systems, industrial GRP production, and bespoke architectural solutions using CNC milling, 3D printing, and digital design. This evolution reflects our commitment to innovation, quality, and comprehensive service for clients across the Kingdom.

Our Strength

With over 42 years of proven experience, STATION GROUP stands as a trusted leader in the construction and engineering industry. Our strength lies not only in our longevity but in the expertise of our highly skilled workforce, engineers, technicians, and administrators, who bring precision, creativity, and dedication to every project.

We pride ourselves on a culture of efficiency, punctuality, and reliability, ensuring that every commitment is met with excellence. By combining technical knowledge with innovative practices, we consistently deliver solutions that exceed client expectations.

Vision & Mission

Our Vision

To establish strong regional recognition in the construction industry and set the benchmark for quality, leadership, and integrity wherever we operate. We aim to:

- Drive innovation through advanced technologies and sustainable practices.

- Build lasting partnerships based on trust, transparency, and excellence.

- Empower our workforce with continuous learning and professional growth.

- Champion sustainability and environmental responsibility for future generations.

Our Mission

- Achieve continuous growth in quality across all departments of our organization.

- Be recognized as the contractor of choice in the region, distinguished by our work methods, advanced technology, and human resource excellence.

- Pursue excellence through commitment, knowledge, and the expertise of our highly skilled engineers, driven by an unwavering desire to deliver quality, on-time, and profitable projects.

- Foster long-term partnerships with clients by consistently exceeding expectations in safety, reliability, and performance.

- Embrace innovation and adaptive technologies to provide sustainable, future-ready solutions.

- Uphold the highest standards of integrity, transparency, and accountability in all business practices.

Why Choose Us

Your Contractor of Choice

Becoming the Contractor of Choice requires more than low prices. At STATION, we deliver individual solutions earning trust through performance.

Always Improving

We strive to meet the needs of today without compromising tomorrow, continuously enhancing our methods and stay ahead.

Honest and Dependable

Our expert teams are carefully selected for each client. Highly trained and resourceful, they apply ingenuity to solve challenges.

Quality Commitment

Our work speaks for itself. Quality and customer satisfaction are not just goals—they are the foundation of our reputation.

We Are Creative

As an industry leader, we consistently develop innovative methods and solutions, ensuring benefit from forward-thinking.

Client-Centric Approach

We listen first, then deliver. Every solution is tailored to the unique needs of each client, ensuring collaboration.

Proven Reliability

Our track record demonstrates consistent delivery of complex projects on time, within budget, and to the highest standards.

Technology Performance

We leverage adaptive forming, CNC milling, and digital innovations to achieve precision, efficiency, and durability.

Divisions

Architectural Facade Composites

Station Group has established itself as a leader in the design, manufacture, and execution of architectural façade composite solutions for residential, commercial, and landmark projects, driven by a strong commitment to innovation and quality.

In pursuit of greater excellence, Station Group proudly collaborates with its sister company, United Arabia Co. (UAC) in Syria, specializing in GRC (Glass Fiber Reinforced Concrete). This partnership unites expertise and resources, enabling us to deliver advanced architectural solutions that combine durability, creativity, and precision.

Our exterior façade products are available in a wide range of architectural styles, textures, finishes, and color shades, helping architects and developers achieve distinctive, modern building designs. Each solution is engineered to deliver durability, visual impact, and long-term performance.

All processes are carried out in strict compliance with international standards, ensuring reliability, durability, and client confidence. By combining advanced technology with creative design, Station Group delivers best-in-class development solutions that balance cost-effectiveness, performance, and architectural beauty.

Our team includes architects, engineers, construction specialists, and business professionals who share a strong commitment to improving the sustainability of both operations and the built environment.

Our division specializes in a diverse range of composite materials, each tailored to meet specific project requirements and environmental conditions:

- Integrated Concrete Composite Material

- Glass Fiber Reinforced Concrete (GRC)

- Glass Fiber Reinforced Polymer (GRP/FRP)

- Glass Fiber Reinforced Gypsum (GRG)

- Ultra High-Performance Concrete (UHPC)

- Digital Art Works & CNC-based Architectural Solutions

- Durability: Resistant to severe weather conditions, corrosion, and environmental stress.

- Design Flexibility: Freedom to create complex geometries, textures, and finishes.

- Cost-Effectiveness: Optimized production methods reduce material usage and installation time.

- Client-Centric Approach: Close collaboration with clients ensures satisfaction and tailored solutions.

- Sustainability: Long-lasting materials with reduced environmental impact.

At Station, we thrive on incorporating quality and aesthetics into construction requirements. Our architectural precast composites are not only functional but also enhance the visual identity of projects. By leveraging advanced composites such as GRC, GRP, GRG, UHPC, and digital art technologies, we provide solutions that are innovative, reliable, and future-ready.

Glass Fiber Reinforced Concrete (GRC) is a composite material that uses alkali-resistant glass fibers instead of steel for reinforcement. Typically cast in thin sections, GRC offers lightweight strength, durability, and design flexibility. Station has pioneered GRC solutions, completing over 500 projects and earning a reputation as the national leader in GRC technology.

- Proven Expertise: Decades of technical experience and 500+ successful projects.

- Innovative Detailing: Unique methods of design, manufacturing, and installation.

- Client Confidence: Trusted for solving complex design and construction challenges.

- Superior Quality: Compliance with international standards ensures long-lasting performance.

- Wall panels and façades

- Window surrounds and column covers

- Cornices, brackets, quoins, and copings

- Domes, soffits, pilasters, and railings

- Site furnishings, planters, bollards, urns, and tables

- Strength: Glass fibers provide tensile strength higher than steel; a 5% fiber mix achieves compressive strength of 6,000–8,000 psi.

- Durability: Resistant to salt spray, moisture, and freeze-thaw cycles. Performs better than conventional concrete.

- Longevity: Testing confirms GRC’s lifespan equals or exceeds precast concrete.

- Fire Resistant: Mineral-based, will not burn.

- Lightweight: 80–95% lighter than solid concrete.

- Design Freedom: Can be cast into virtually any shape.

- Aesthetic Versatility: Available in integral colors or paint-grade finishes.

- Environmental Benefits: Lower impact than stone or conventional concrete.

- Disaster Resistant: Proven resilience against hurricanes, fires, and earthquakes.

Colors: Standard limestone shades plus custom-matched options.

Textures: Smooth, sandblasted, honed, exposed aggregate, travertine, wood grain.

Shapes: Flats, curves, domes, spheres, waves, and intricate forms.

Glass Fiber Reinforced Polymer (GRP/FRP) is a composite material made of a polymer matrix reinforced with glass fibers. It is widely recognized for its lightweight strength, corrosion resistance, and design flexibility. Station has successfully designed, manufactured, and installed GRP solutions across residential, commercial, and infrastructure projects.

- Lightweight Strength: Weighs significantly less than concrete or steel.

- Corrosion Resistance: Ideal for coastal and industrial environments.

- Applications: Domes, canopies, industrial covers, marine structures, and decorative claddings.

Glass Reinforced Plastic (GRP), also known as Fiberglass or FRP (Fiber Reinforced Plastic), is one of the world’s most versatile composite materials. Its architectural potential was famously revealed in 1967 during the attempted demolition of Disneyland’s House of the Future, which proved nearly indestructible.

Since then, GRP has become widely adopted across construction, transportation, marine, and aerospace industries.

- Extremely Strong: Up to seven times the flexural strength of steel.

- Lightweight: High strength-to-weight ratio reduces structural and shipping costs.

- Seamless Construction: Sections can be bonded to form watertight assemblies.

- Highly Moldable: Ideal for complex shapes, textures, and intricate details.

- Low Maintenance: Will not rust, corrode, or require cathodic protection.

- Disaster Resistant: Performs exceptionally well in extreme weather conditions.

- Superior Aesthetics: Can replicate bronze, wood, stone, iron, and more.

GRP is widely used for:

- Architectural domes, vaults, minarets, and decorative cladding.

- Parking structures and façades.

- Boat hulls, automotive components, aircraft parts, and storage tanks.

Glass Fiber Reinforced Gypsum (GRG) is a lightweight yet strong composite material made from high-density gypsum plaster reinforced with glass fibers. Recommended for interior use only, GRG is ideal for moldings, ceilings, and columns.

Why Choose GRG? It is flame resistant, lightweight, easy to install, and offers immense design flexibility for interior decor.

UHPC is an advanced cementitious composite characterized by exceptional strength, ductility, and durability. Station produces UHPC elements tailored to client requirements, achieving compressive strengths of 150 MPa or higher.

- Durability: Nearly impermeable, highly resistant to weathering.

- Performance: High ductility and impact resistance.

- Applications: Bridges, high-rise facades, marine structures, and industrial components.

Digital Art in precast composites integrates advanced digital technology into the creative process. We specialize in:

- Photo Engraved Concrete

- Calligraphy Carving

- 3D Printed Stained Glass

- Fire Impression Illumination

- Parametric GRC & Multicolor Pigment GRC

- Embossed Handmade Simulation

- Transparent Marble & Translucent Concrete

- Mosaic Integration & Heritage Impression

- Parametric GRC: Complex geometries and parametric designs.

Advantage: By merging artistic creativity with advanced technology, Station delivers digital art solutions that transform architectural precast composites into functional works of art.

Station Industrial Facility

Building Restoration & Rehabilitation

Heritage & Modern Contexts: Station Group delivers both specialized and conventional restoration approaches, ensuring the ideal solution for every project from small assignments to multi‑faceted, full‑scale restorations. Our expertise extends to UNESCO‑recognized sites in Saudi Arabia and Syria’s centuries‑old monuments, blending authenticity with modern functionality to preserve world‑renowned heritage.

- Supporting clients in identifying structural concerns.

- Development of feasibility studies for heritage and modern structures.

- Turn‑key delivery and management of the complete process.

- Design/Build contracts and long‑term maintenance agreements.

- Condition Assessment: Thorough evaluation of building integrity, damage, and deterioration.

- Documentation: Reports, photographs, and drawings of existing conditions.

- Permitting: Obtaining necessary approvals from authorities.

- Concrete Repair: Repair/replace columns, beams, slabs, foundations.

- Masonry Repair: Walls, arches, and vaults.

- Steel & Wood Repair: Beams, joists, connections, and decking.

- Cleaning: Removal of dirt, grime, and substances.

- Masonry Pointing: Repair of mortar joints.

- Window/Door Restoration: Frames, sashes, glazing, and hardware.

- Roofing: Shingles, tiles, or membranes.

- Plaster Repair: Walls, ceilings, and cornices.

- Painting: New coatings for interiors and trim.

- Flooring & Ceilings: Repair/replace hardwood, tile, carpet, or acoustic tiles.

Rehabilitation: Improving a building's functionality and safety while maintaining its historical character.

Restoration: Returning a building to its original condition using traditional materials and techniques; aims to preserve historical integrity.

- Rehabilitation: Repairing integrity, weatherproofing, energy efficiency.

- Restoration: Repointing masonry, replacing elements, restoring original paint.

- Rehabilitation: Stabilizing objects for continued use.

- Restoration: Meticulous cleaning, removing additions, traditional finishes.

- 3D Printing & Digital Art

- Perforated Screens & Pergolas

- Boulders, Rocks & Rammed Earth Walls

- GRC / GRP / GRG & FRP Products

- Metal Casting (Bronze, Brass, Aluminium)

- Wood Fabrication & Artistic Glass

- Artistic Ceramic & Stone Works

- Planters, Benches & Flooring Tiles

- Fiber Optic Lighting & Honeycomb Panelling

- Tuckpointing & Mortar Joint Repair

- Thru-Wall Flashing & Sealant Replacement

- Facade Modification & Cleaning

- Concrete Injection & Structural Repairs

- Prefabricated Facades

- Building Evaluation

- Punch List: Completion of all items to ensure full restoration.

- Final Inspections: Verification of compliance with all codes and standards.

Concrete Repair

STATION’s expertise spans both specialized and conventional concrete repair approaches, ensuring the ideal solution for every project. From minor aesthetic repairs to multi-faceted full-scale restoration, STATION delivers excellence across all phases of the structural lifecycle.

We act as a strategic technical partner, supporting clients in identifying structural concerns and developing feasibility studies to determine the most durable and cost-effective repair options. Our turn-key delivery model encompasses Design/Build contracts, management of the complete repair process, and long-term Maintenance & Renovation services.

Concrete is a strong, durable material used in critical structures such as foundations, bridges, buildings, water tanks, and dams. However, without proper maintenance, it is subject to deterioration driven by original material quality, exposure conditions, and design standards.

The most common cause of failure is rebar corrosion. When reinforced steel is exposed to excess chlorides or carbon dioxide (carbonation), it undergoes an expansive oxidation process. This rust expansion creates internal tensile stress, leading to cracking, spalling, and eventual structural bursting. Other primary causes of concrete failure include Alkali-Silica reactions (ASR), aggressive chemical attacks, mechanical impact damage, and frost expansion.

STATION applies proven repair techniques tailored to each project’s unique environmental and structural needs. Our methodology ensures that structural integrity is not just restored, but enhanced against future degradation.

- Structural & Cosmetic Systems: Comprehensive repair for surface and structural defects.

- Structural Strengthening: FRP (Fiber Reinforced Polymer) and conventional methods.

- Injection Treatments: High-performance epoxy and polyurethane resins for cracks and voids.

- Industrial Rehabilitation: Restoration of concrete silos and large-scale industrial structures.

- Shotcrete Technology: Specialized repair and protective application for heavy infrastructure.

- Surface Protection: Abrasive blasting and chemical-resistant protective coatings.

- Chemical Treatment: Structural stabilizers and corrosion inhibitor applications.

- Grouting & Patching: Precision overlays and structural leveling systems.

Construction Services & Maintenance

Founded to serve specialized contracting needs across the Kingdom of Saudi Arabia, Station Group has evolved into a multi-disciplinary powerhouse serving prestigious clients in the industrial, commercial, and governmental sectors. Our operational footprint encompasses all aspects of general and specialized maintenance, as well as light and medium construction services. From critical infrastructure to specialized oil sector facilities, our teams are driven by a commitment to technical excellence and high-level supervision.

At Station Group, the client’s requirements, no matter how specific or complex, remain our central focus. We have built a solid reputation based on integrity and performance, working closely with design teams to ensure project outcomes meet exact specifications. Our success is rooted in delivering precisely what is needed while maintaining rigid standards for efficiency, safety, and cost-effectiveness. This philosophy has earned us repeat contracts and long-term trust from the Kingdom's most demanding sectors.

Our construction and maintenance division acts as the anchor for the Group's specialized subsidiaries, providing a unified management structure for complex projects:

- General Maintenance: Specialized and preventative programs for industrial assets.

- Infrastructure Services: Light to medium construction for civic and private developments.

- Oil & Energy Sector: Technical facility maintenance and specialized support.

- Turn-key Solutions: Single-source delivery from ground-breaking to handover.

- Strategic Supervision: High-level oversight ensuring budget and timeline adherence.

- Innovative Fabrication: Integration of advanced composites and architectural precast.

Through dedication and innovation, Station Group continues to expand its portfolio to include waterproofing, concrete repair, fireproofing, architectural precast composites, and advanced fabrication solutions, ensuring we remain at the forefront of the Kingdom's construction industry.

Engineering & Technical Services Oil & Gas

Our Scope of Activities

We deliver specialized solutions in oil and gas engineering and maintenance, including:

- Cathodic Protection Systems: Prevention of corrosion on critical assets.

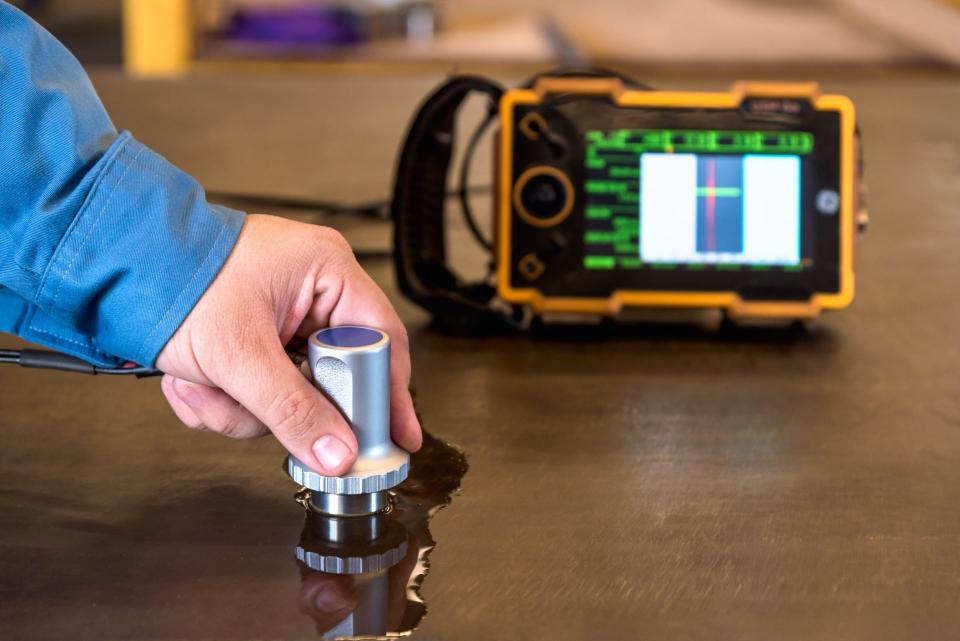

- Non-Destructive Testing (NDT): Ensuring material integrity without damage.

- Heat Treatment: Preheating and post-weld heat treatment (stress relieving).

- Testing & Inspection: Comprehensive programs for quality assurance.

- Leak Sealing Operations: Emergency and maintenance sealing services.

- Refinery Solutions: Maintenance and upgrading for processing facilities.

We design and implement cathodic protection systems tailored to pipelines, tanks, offshore facilities, and concrete structures. Our approach ensures cost-effective, durable protection with minimal maintenance requirements. Our engineers utilize the latest industry standards to mitigate corrosion effectively.

Key CP Services:

- Pre-Design Site Survey: Assessment of site conditions affecting corrosion control (e.g., buried pipelines, tank bases).

- System Design: Preparation of survey reports, design calculations, bill of materials, detailed drawings, and installation procedures.

- Installation: Direct execution or supervision of CP system installation across the Arabian Gulf region.

- Testing & Commissioning: Adjustment of current and voltage to achieve optimal protection levels.

- Monitoring: Scheduled inspections and performance tracking to ensure continuous system efficiency.

Our division provides advanced metallurgical and welding-related services to ensure structural integrity without causing damage to the assets. We specialize in precise thermal applications:

- Post Weld Heat Treatment (PWHT): Stress relaxation, tempering, and hydrogen removal using electrical resistance or furnace firing methods.

- Pre-Heating: Minimizes cracking risks by reducing temperature differentials during welding processes.

- Normalizing/Annealing: Enhances tensile strength and impact resistance of steel for improved fracture resistance.

- Solution Heat Treatment: Restores corrosion resistance in stainless steels through controlled heating and rapid cooling.

- Refractory Dry-Out: Gradual heating of furnace insulation per manufacturer guidelines to remove moisture.

We provide a full suite of inspection and quality assurance techniques to safeguard industrial assets and ensure compliance with international safety codes:

- Paint Curing: Controlled drying of protective coatings for maximum durability.

- Positive Material Identification (PMI): On-site analysis of metal composition for compliance verification.

- Radiography (RT): X-ray and gamma ray testing with portable equipment and mobile darkrooms.

- Ultrasonic Testing (UT): Lamination checks, thickness measurement, and corrosion monitoring.

- Magnetic Particle Testing (MPT): Flaw detection using AC/HWDC current flow and permanent magnet techniques.

- Liquid Penetrant Testing (LPT): Surface defect identification using daylight or fluorescent dye methods.

- Leak Detection: Vacuum box, bubble/gas leakage, and ultrasonic systems for airtight integrity.

- Hardness Testing: Verification of material strength using portable manual or electronic instruments.

- Coatings Inspection: Holiday detection for coal-tar or bitumen wrapping and paint thickness measurement.

- Site Assessment & Survey

- Design & Engineering

- Gulf-wide Installation

- Commissioning & Tuning

- Maintenance Monitoring

- Sacrificial Anode Systems

- Impressed Current Systems

- PWHT (Stress Relieving)

- Pre-Welding Heating

- Annealing & Normalizing

- Refractory Dry-Out

- Furnace & Localized Heating

- Radiography (RT)

- Ultrasonic (UT)

- Magnetic Particle (MPT)

- Liquid Penetrant (LPT)

- Composition Analysis (PMI)

- Visual Inspection (VT)

- Eddy Current Testing

- Refinery Maintenance

- Leak Sealing Operations

- Hardness Testing

- Coating & Holiday Detection

- Asset Life Extension

- Pipeline Integrity Management

- Quality Control Audits

Fireproofing & Passive Fire Protection

Station Group’s experience and know-how include both specialized and conventional fireproofing approaches to deliver the ideal solution for all steel structure projects as well as mixed/concrete ones. Whether it is a commercial, residential, cellulosic project or a petrochemical, industrial, or hydrocarbon project, Station can deliver the exact right services covering:

- Defining the critical path and preparing life safety drawings certified and attested by third-party consultants and legal authorities.

- Assessing project fire pool criteria: cellulosic or hydrocarbon.

- Recommending the most competitive fireproofing materials (Intumescent / Cementitious).

- Designing required material thicknesses as per steel member sections.

- Managing all technical submittals, approvals, third-party inspections, and Civil Defence handovers.

Fireproofing is essential for steel structures and similar projects. It provides resistance to fire so that critical structures remain standing and control systems continue to operate until the fire is brought under control.

- The essential feature of fireproofing is preventing the passage of flame or heat, protecting against structural collapse.

- Fireproofing materials are specified for either cellulosic (ordinary) or hydrocarbon fire exposures at various durations.

- Intumescent coatings swell up to fifty times their original thickness, providing effective fire resistance.

- Historically, asbestos was used but has been replaced by safer cement-based products.

- High-rise towers

- Universities

- Hospitals

- Shopping malls

- Stores and warehouses

- Gas plants and refineries

- Petrochemical plants and facilities

- Power plants

- Cementitious Hydrocarbon

- Cementitious Cellulosic

- Advanced coatings that expand under heat to protect steel structures.

- Sealing penetrations and joints to prevent fire spread.

- Encasement of existing metal ductwork.

- Self-supporting ductwork systems.

- Up to 240 minutes fire performance.

- Utilization of existing ductwork.

- Ease of construction with adhesive fix methods.

- Lightweight and cost-effective.

Landscaping & Outdoor Development

The STATION Landscaping Division brings over 20 years of experience in the Saudi and Gulf region. We operate on the philosophy that the quality of outdoor spaces directly impacts lives, prioritizing context and sustainability in every design.

The STATION Advantage (Single-Source Solution):

What separates us from other companies is our ability to provide almost any exterior skin system under one roof. By owning our own production lines, we reduce the need for clients to hire and manage multiple subcontractors.

- In-House Manufacturing: We produce architectural precast (GRC, GRP, GRG, UHPC), wood, and metal fabrications, as well as natural stone.

- Waterproofing Expertise: Backed by over 40 years of experience as a specialized waterproofing applicator.

- Streamlined Coordination: We manage the coordination between various suppliers internally, ensuring a smoother process for the client.

Our Capabilities:

- Hard & Soft Landscaping: Contemporary garden designs, outdoor seating areas, and plant areas.

- Water Features: Design and installation of swimming pools and decorative water elements.

- Furniture: Fabrication and installation of custom interior and exterior furniture.

- Retail & Supply: We offer high-quality plants, landscape lighting, and sustainable products at affordable prices through our retail outlets.

- Site analysis and evaluation.

- Conceptual Drawings and visuals for specific areas.

- Provide developed and detailed landscape master plan based on the approval of client.

- Explanatory visuals (sections and/or elevations and/or perspectives).

- Schematic Planting Plan & Material Layout.

- Coordinate Schematic Designs with other Trades.

- Update Schematic Design Drawings based on Review.

- Prepare hardscape architecture details.

- Prepare Final Planting Plan and Details.

- Prepare Lighting Layout.

- Enlargement Plan, Site details and sections.

- Hardscape Plan and Details.

- Planting Plan and Details.

- Lighting Plan and specification.

- Irrigation Sleeves plan and Layout.

- Landscape Specifications (Hard, Soft, Irrigation).

- Submit Tender Documents to Client.

- Office Support & Meetings.

- Onsite Changes.

- Visits to Suppliers.

- Supervision Reports.

- Weed all agricultural plants and pots.

- Pruning of trees and shrubs; removal of cancers.

- Fix climbers properly.

- Using appropriate fertilizers, pesticides and insecticides.

- Follow-up irrigation works with maintenance employee.

- Train present Labor in the site.

- Monthly Reports.

- Train present Labor in the site.

- Follow up on health status of plants.

- Follow-up on weeding works and pruning.

- Follow-up on growth of climbers.

- Follow-up on fertilizers/pesticides & irrigation efficiency.

- Monthly Reports.

- All structural, MEP, engineering and building architectural services.

- Site investigation and survey (geotechnical/topographical/as-built).

- All necessary approvals from governmental agencies and municipalities.

- Stages 5, 6, 7 (separate fee contract).

Waterproofing

Introduction: STATION offers a wide range of high-quality Waterproofing services to its valued clients throughout the Kingdom. We understand the specific needs of every project and work closely with architects, engineers and main contractors to guarantee the right material is utilised in every case. Our experienced management crew along with our skilled labour is the basis to any successful job. We know what resources and methods will yield the highest productivity for specific budgets and conditions. Our crew is always available to inspect and advise clients on techniques that yield the most economical solutions and recommend the best alternatives for any situation. The best evidence of our reliable craftsmanship is our long-lasting relationships with our clients who repeatedly invite us to work on their projects.

We will certainly be your specialised contractor to solve any of your underground or roof water concerns. Our waterproofing and insulation systems are designed to provide full protection for various interior and exterior applications in the construction industry. STATION has been certified as a well-trained applicator by various top Waterproofing suppliers in Europe and the United States.

Membrane Systems: EPDM – APP – SBS – PVC – HDPE – TPO – Hypalon – Liquid Applied Membranes

Concrete Admixture: CRYSTALLINE WATERPROOFING ADMIXTURE – Integral Capillary Systems

Coating Systems: CRYSTALLINE – EPOXY – ELASTOMERIC CEMENTITIOUS – POLYURETHANE FOAM SPRAY – Polyurea

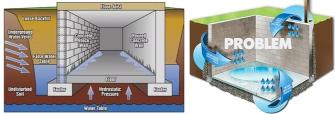

Below-ground Waterproofing: Crucial to most structures to avoid leakage caused by the hydro-static pressure from the water table underground and cracks that occur over time from the soil pressure. The hydro-static pressure will eventually force water into the building structure through its cracks, joints and any permeable substrates leading to structural damage and the likelihood formation of mould, corrosion and other wetness related concerns. STATION offers a wide range of waterproofing solutions for underground structures providing protection from groundwater, soil gases and other contaminants by delivering clients with high performance products backed by our diligent technical service.

External & internal waterproofing systems: External and Internal waterproofing application is necessary to several structures such as drinking water supply channels, irrigation channels, water pipes, water tanks and reservoirs as well as other artificial ponds. These structures are constantly exposed to pressing water and leakage is common after a few years of use. STATION solutions offer several high-end materials whether membrane or coating systems to provide long-term protection of both internal and external surface areas of all kinds of simple and complex reserve tanks.

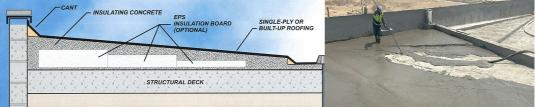

Roofing insulation waterproofing systems: Roofs are critical sections of any structure as it fulfills an important role in facility protection. Every Roof structure has a unique character, whether it is flat or domed. As the highest point of a building, roofs are continuously, year after year, degraded by various factors such as sunlight, wind, rain and others, frequently leading to costly leaks and higher energy bills. We provide our clients with different means to ensure that water is carried away from the building without causing any dampness in walls or roofs. Our engineered Roofing Systems combine both Thermal Insulation and Guaranteed Waterproofing.

Lightweight insulating concrete systems (LWIC): The Lightweight Insulating Concrete (LWIC) roof system is a sustainable, high-performance monolithic substrate alternative to other traditional insulation systems. Combining the unique properties of both lightweight insulating concrete and polystyrene foam insulation board, it leads to a smooth surface ideal for roofing application. LWIC addresses customizable slope-to-drain, dimensional stability, re-roofability and the ability to mechanically fasten the roofing membrane to the insulation.

Environmental pond lining: Pond and Environmental liners are frequently used to prevent water leakage for projects that are using storage ponds and tanks for water containment. Heavy duty liners can also be used to contain oil, waste, or chemicals. Our technical experts assess every lining project case differently to provide the most economical value. Factors considered are size, containment substance, penetrations, and current state of area.

Wet areas waterproofing: Allows bathrooms, laundry rooms and kitchens to become moisture resistant. Critical due to constant use of water and humidity. Points of leakage include wall joints and pipes. If moisture spreads to the concrete, it causes significant damage to rebars. It is key to install an impermeable layer over the concrete to stop the spread of moisture.

Epoxy Flooring: Durable, chemical-resistant flooring solutions for industrial and commercial applications, food processing plants, and warehouses.

- Underground Systems (Tanking)

- External / Internal Tank Systems

- Corrosion Protection & Control

- Expansion Joints / GRP Tank Lining

- Pile Treatment & Head Capping

- Environmental / Pond lining

- Bentonite Composite Sheet WP

- Damp proofing and Waterproofing

- Built-Up Coal Tar Waterproofing

- Structural Base Grouting

- Concrete Structural Repair

- Resin Injection & Grouting

- Shotcrete (Wet & Dry Spray)

- Patching & Overlays

- Crack Sealing & Repair

- Lightweight Insulating Concrete (LWIC)

- Roofing & Thermal Insulation Systems

- Membrane Roofing (SBS, APP, EPDM)

- Built-Up Bituminous Roofing

- Modified Bituminous Membrane Roofing

- SBS Mod Bituminous Membrane Roofing

- Thermoplastic & Elastomeric Roofing

- Protected Membrane Roofing (PMR)

- Fluid-Applied & Coated Foamed Roofing

- Roll Roofing Systems

- Roofing and Siding Panels

- Thermal Protection & Insulation

- Exterior Insulation Finish Systems (EIFS)

- Epoxy Flooring & Wall Coating

- Traffic Coatings (Vehicular & Pedestrian)

- Water Repellents & Sealing

- Vapor Retarders / Air Barriers

- Cementitious and Reactive WP

- Self-Adhering & Fluid-Applied WP

- Sheet Metal Waterproofing & Roofing

- Sheet & Bituminous Sheet WP

- Chemical Resistant Coatings

- Flashing and Sheet Metal Systems

- Roof and Wall Specialties (Pavers)

- Passive Fireproofing / Fire stopping

- Joint Protection & Sealants

- Preformed Joint Seals

- Roof Accessories & Hardware

Factory

Our state-of-the-art factory is equipped with advanced machinery and technology to produce high-quality architectural precast composites, hardscape products, and concrete furniture. With a focus on innovation and sustainability, our factory enables us to meet the diverse needs of our clients while maintaining strict quality control standards. From design to production, we ensure that every product meets our commitment to excellence and durability. Our manufacturing division currently has over 400 manpower plus 100 installers operating on different shifts, ensuring round-the-clock productivity to meet aggressive project timelines. STATION is supported by our own PI insurance, ensuring all our designs comply with international industry standards.

There are more than 20 CNC machines in various sizes and functionalities within our facility. These machines perform various engineering processes to transform raw materials into complex architectural components. Our capabilities include subtractive manufacturing (high-precision milling and lathing), laser and waterjet cutting, and advanced material shaping for metal and composite profiles. We process a wide range of materials, including concrete, polymer composites, metal, wood, polystyrene, and natural stone.

The company's engineers and skilled technicians possess expert knowledge in CAD/CAM programming strategies to achieve digital engineering production. All of our designs and specifications are written by our CSSW qualified technical team, supported by our in-house Structural & Survey Engineers. This internal synergy facilitates shortening the cycle of any approvals or queries coming directly from the site. By integrating design and manufacturing under one roof, we eliminate bottlenecks and ensure that what is designed is precisely what is built.

STATION operates under strict adherence to global engineering benchmarks. We ensure that all precast and composite products are tested and verified to meet industry standards, including PCI (Precast/Prestressed Concrete Institute) for structural integrity, GRCA (Glass Fibre Reinforced Concrete Association) for GRC excellence, and ASTM International for rigorous material testing.

- Subtractive Manufacturing: High-precision milling, lathing, and punching.

- Cutting Technologies: Laser, Waterjet, Hot Wire, and Fast Wire systems.

- Material Shaping: Bending, rolling, and multi-material profile processing.

- Specialized Composites: Architectural GRC, GRP, GRG, and UHPC manufacturing.

- Fully automated GRC batch plant with colour mixing technology.

- Fully automated remote controlled distribution mortar.

- Top of the line machinery and raw material for mold & GRC fabrication.

- 10 types of sand and aggregates able to produce either dry mix or wet mix.

- Tilting tables & Magnetic shuttering system.

- Remote control casting and distribution.

- Boiling system for curing and controlled quality.

- Vacuum Infusion technology for GRP elements.

- R.T.M technology & P.U Injection for double face G.R.P element.

- C.N.C cutting marble boards & N.C mixing marble component.

- C.N.C plasma machine (up to 12 meters).

- C.N.C press brake (up to 6 meters).

- C.N.C shear, band saw, iron worker machines.

- N.C wrought iron bending machine & Automatic welding.

- TIG, MIG, Stick welding machine.

- Galvanizing facility & Electroplating (copper, nickel and chrome).

- C.N.C milling & C.N.C cutting.

- Painting and Polishing.

- 3D model scanning technology (up to 50 micron).

- Topcon Building Surveying System.

- 3D Printing technology.

Architectural Specialized Products

Regional Presence

Through our regional network, Station Group ensures quality service across the GCC and Levant.

- Saudi Arabia: Headquarters in Jeddah with branches in Riyadh, Dammam, Jizan, Yanbu and Madinah.

- Syria: Offering construction, restoration, engineering, Oil & Gas, landscaping services to support development initiatives.

Location: Rif Dimashq Governorate, Qudsaya, Syria